A Bunch of Lonesome Heroes: The factory at sea

9 February 2015

20.00

“Going forward and glancing over the weather bow, [… the] prospect was unlimited, but exceedingly monotonous and forbidding; not the slightest variety that I could see.” Herman Melville, Moby Dick

For the next few days, we shall be traveling on the sea in a monotony of sunshine, humidity, warmth, and reading pleasure. Only near Bab al-Mandab will the monotony be relieved, whether by the sights of nearing mountains lowering over the strait or by raised security level (from 1 to 2) as we cross through the pirate alley. It is already quite warm outside, and we are properly in the Red Sea, beyond where we can see the traffic of other ships or the coasts. In the afternoons, I quite like my circumnavigation of the upper deck again and again. It is a kind of tawaf; a kind of pilgrimage in which at last I have a chance to say hello to the crew, however briefly. They are so hard at work, welding, sanding, high-pressure cleaning of the deck, painting rust spots, sweeping away the mud that the massive anchors brought up with them from the Mediterranean as we waited for permission to cross into Suez. I march around the deck again and again – around 6.5 times makes an hour, saying hello to the smiling Filipino crew members, the electrician who is sometimes wandering about, and others that pass through. And occasionally cheat and stop at the bow, as close to the front as I can, and stare out to the sea. There are fewer (or no?) refrigerated boxes towards the front of the ship, and there, the sound of the sea drowns out even the massive engine’s thrumming.

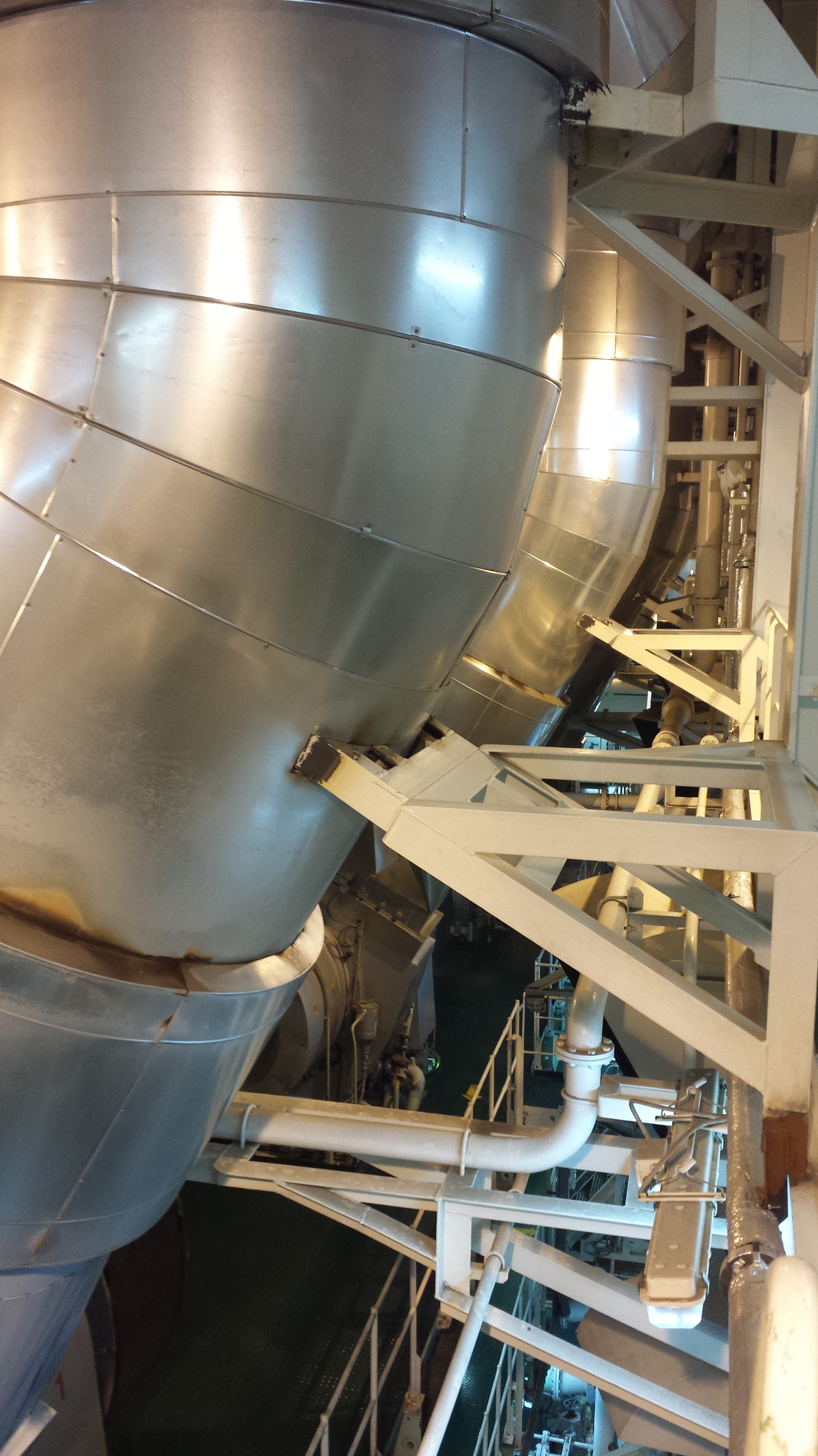

This morning, we passengers were shown around the engine room by one of the crew members. Getting there through the corridors in the lower deck with the low hum of the engine and the heat running through feels a bit like a horror film, especially as we passed one light that kept blinking. It is the sterility of the space down there, all surfaces painted beige, the sameness relieved only by the silver insulation of the pipes that run the length and little painted red triangles on the edges of the ribs of ship. There are manholes down to the ballast tanks, which we have to watch out for, as sometimes they can be open. I was told when we visited the citadel the other day that in the winter in northern Europe, the lower deck can be covered in frost, and in the summer, passing through tropical zones, it can be hot as hell. Literally.

The engine room visit was rather amazing. We had to wear noise-cancelling headphones and were given a tour by one of the Filipino engine room crew. There is that enormous engine with its 14 cylinders producing 107,000 horsepower. With the colossal crankshaft whose rotation drives the ship forward. And the deep pulsation of the engine which you can feel in your bones at 90 rpm, it beats beats beats in some visceral infra-hearing sort of way, traveling through your muscles, magnetising the rhythm of your heart to its own. I recorded the sound, but the recording is all a kind of barely thrumming static. But being there, inside the ventricles of the heart of the engine, with what felt like the valves opening and closing and the aorta of the ship throbbing, the rhythms and vibrations travel through the walls, floors, through the air into your bones and body. At this speed, the engine consumes around 200 tonnes of fuel a day, fuel that is bunkered only in Europe apparently and which has to last all the way to China and back.

This vast engine is most affected by humidity apparently. The second engineer told me that at Bab al-Mandab, sometimes it is so humid that the engine produces something like 200,000 litres of water a day, absorbed from the air and transformed into a cataract pissed into the sea. There are other things about the ship that reminds me of a body. Tonight, we have been sailing into a head-wind of 15-20 knots under a star-drunk sky (we seem to be following the trail of the Milky Way as we speed south closer to the Sudanese coast than to the Saudi one).  The wind blows through the gaps of the containers and the strange groaning squally sound it produces reminds me of the ultrasound thrum of a pulsating wash going round and round inside one’s womb, like the whoosh of blood boiling through the bigger veins and arteries of a body.

The wind blows through the gaps of the containers and the strange groaning squally sound it produces reminds me of the ultrasound thrum of a pulsating wash going round and round inside one’s womb, like the whoosh of blood boiling through the bigger veins and arteries of a body.

But back to our morning adventure: Of all the shipboard spaces, the engine-room is most like a factory (which if Capital Vol II is right, the ship carrying this cargo to a market where it can be sold for higher value is indeed part of the production cycle, and therefore, a kind of factory). Enormous tools everywhere and enormous skill required to work with all of that. No sight of the sea, no feeling of the wind, or the infinite (I hang my head in shame), and if there is a movement visible, it is not of the ship cutting through water, but of machineries’ inner parts moving one another in a kind of methamphetamined tango. Down there, in the workshops and on the floor of the engine-room, cadets and engineers and oilers and fitters are at work in the heat, and objects are oily and heavy and hot and the air smells like diesel and metal. This is the ship sans the romance, and labour that is not just about tedium or exhaustion of erratic shifts, but about lifting massive objects, affixing things to one another, or to chains, welding, digging through oil and grime. The danger of electrocution or chemical burns, or heat burns, or heat exhaustion, or falling and cracking your skull or spine on these massive angular sharp edges and ledges.

There are rooms within rooms and spaces within the larger spaces where tools are arranged in orderly arrays, gleaming in the heat. Somehow this reminds me of a ship on which the great Allan Sekula travelled and the story he tells about it. The ship was the first ship built in South Korea by Daewoo (incidentally the same company that has built CMA CGM Corte Real) for the now-defunct US shipping company, Sea-Land (also notable for having been the shipping company set up by Malcom (sic) McLean, the inventor of the container as a form of intermodal transport). Sekula writes

When an American crew picked up the first of these ships from the Daewoo dockyard, completed the sea trials, and began the voyage back across the Pacific, they discovered in the nooks and crannies of the new ship a curious inventory of discarded tools used in the building of the vessel: crude hammers made by welding a heavy bolt onto the end of a length of pipe, wrenches cut roughly by torch from scraps of deck plate. Awed by this evidence of an improvisatory iron-age approach to ship building, which corresponded to their earlier impression of the often-lethal brutality of Korean industrial methods, they gathered the tools into a small display in the crew’s lounge, christening it “The Korean Workers’ Museum.”

I am fairly certain that now, some decades later, Daewoo, through probably still brutally exploiting its workers, is no longer in that iron-age stage of ship manufacture: looking at that crankshaft below as it turns at 90 revolutions per minute, around 1.5 turns every second, inside the ribcage of the engine –that metallic leviathan’s skeleton- I am fairly sure that they have surpassed our age in their construction methods.

In some ways, thinking about us descending level by level by level into the bowels of the ship where physical, embodied work is being done reminds me a bit of the chapter in Moby Dick where captured whales are processed in the bowels of Pequod. Here he is:

And thus the work proceeds; the two tackles hoisting and lowering simultaneously; both whale and windlass heaving, the heavers singing, the blubber-room gentlemen coiling, the mates scarfing, the ship straining, and all hands swearing occasionally, by way of assuaging general friction.

Not much singing in the engine room of Corte Real, but there is a sense of the choreography of work, of its perfect fit together that somehow corresponds to the fleshy labour of Melville’s whalers, “every sailor a butcher.” In his stubbornly materialist reading of Moby Dick, CLR James pauses on the Try-works chapter and those proximate to it most carefully, prises their mechanics loose, and describes the choreography of the works involved in stripping the whale as the basis of a kind of solidarity, “a world-federation of modern industrial workers [who] owe allegiance to no nationality… They owe no allegiance to anybody or anything except the work they have to do and the relations with one another on which that work depends.” Perhaps because our ship has fewer nationalities on it than I have read about in other instances, the national languages (Tagalog and Serbo-Croat and probably one of the southern Indian languages too) seem to make islands of groups of workers, bridged by English. That contraction in the number of nationalities is a surprising difference between Corte Real and Melville’s ships in his very many gorgeous maritime stories.

Later:

On Allan Sekula’s Fish Story

Every time I read the late Allan Sekula’s gorgeous prose while looking at his photographs I fall in love with him a bit more, if it is possible to be besotted with a dead man. That picture of his included in “Between the Net and the Deep Blue Sea,” winking as he dives up from the sea outside Bill Gates’ house, of all places, just takes my breath away. How could you not fall for him? Such a vast store of erudition about the inner machinery of maritime commerce and nautical wars; such a beautiful weaving of cinematic stories, breathtakingly illuminating imagery with the words of Walter Benjamin and Proust; Mumford Melville and Manet; such an insightful reflection on forgotten spaces and places – and even as he cuttingly critiques “humanism,” the seriality of his images constantly introduce humans into the shabby or epic machine spectacles he photographs initially without a person in them (if one doesn’t count the congealed labour of making all the machinery he photographs).

The weird origins of Korean shipbuilding in the 1970s can be traced in part to the purchase of plans from bankrupt Scottish yards on the River Clyde. With the second Industrial Revolution repeating itself on the shores of Mipo Bay, a number of unemployed Glasgow shipwrights migrated to Ulsan…

The greater Hyundai empire began as a fledgling construction firm building bases for the Americans. First during the Korean War, then later in Vietnam. … In the film version of White Badge, Vietnamese peasants are massacred by Koreans within sight of a busy superhighway that could not have existed in Vietnam during the war, but that did come to be built in Korean by the same construction company that got its start building roads and barracks for the Americans. The scenographic “mistake,” just barely discernible in the far background of the sot, is a clever way of looping forward in time, drawing a link between Korean and Vietnam that looks forward and not simply back to the similarities between the Korean and Vietnamese wars.

And in fact, the ship on which I am afloat, CMA CGM Corte Real, was itself manufactured in the Busan factories of Daewoo, and Hyundai has built the generators on this ship. And I wonder if there is some ancestral memory of river Clyde buried through the body of this ship passed from those Glaswegian shipwrights to their industrial progenitors.

Of course what else interests me about the above is the extent to which my trawl through Middle East Economic Digest back issues produced the impression that the ports; shipyards; pipelines; “military cities” and the like being built in the boom years after 1973 on the Arabian Peninsula were being built by Korean firms. A 1977 report, for example, says that “Last year, about 30 South Korean companies secured more than $2,000 million worth of construction contracts in the Middle East, which alone took more than 90 percent of Korean overseas construction activity.” And this is only construction companies: what about engine-builders, and dockyards machinery manufacturers, and contractors of other sorts? What about the skilled labour that flowed for a time from Korea to the petroleum-producing countries (the way other Southeast Asian countries now export labour there today). Later, in 1980, when the economic boom had given way to crisis, MEED reported “reassessments” on the part of Korean companies, “as their labour costs rise and competition for fewer big contracts become tougher.” Even in the tough conditions, the Korean share of the Saudi construction market was estimated at 23 percent!

Meanwhile, in the same 1977 issue of MEED, there is a small item about how Sharjah is hiring South Korean stevedores in order to make its ports “more attractive to shipping companies.” South Korea’s Sun Lee [presumably a recruiting company] was to provide “100 Koreans to augment the port labour force of 500 Indians and Pakistanis.”

I wonder in all the vast literatures of political economy written about the “miracle” of South Korean economic “take-off” and all the arid and politically dubious debates about authoritarian rule acting as a precondition of economic growth (all the stuff I had to read as a grad student 15 years ago and more), anyone has looked at the role these Middle Eastern contracts played in the growth of the chaebols. Something to pursue perhaps.